Infrastructure

Manufacturing Facility

We have a state-of-the-art manufacturing facility located at Dehgam near Ahmedabad, Gujarat, India with 10,000 Sq. Mt of Area. This facility is capable of production capacity of up to 22,400 man hours per week, as per the standard dual-shift pattern.

Manufacturing Facility

Our manufacturing unit has the following facilities:-

- Appropriate supply of industrial cutting welding gases like Oxygen, Acetylene, Argon, CO2 etc along with necessary utilities required for manufacturing, testing & quality check of all the fabricated equipment.

- We follow standard welding procedures and various welding codes including ASME, AWS and other specification.

- We have a provision for canteen facility and a guest house with premises for guest and labour for accommodation.

Manufacturing Facility

01. Machine, Metallurgy and Equipment

Below is the list of equipment that helps us to simulate operating conditions and to provide world class finished goods:-

- Plasma Cutting Machine

- Profile Cutting Machine

- Plate Rolling and Bending Machine

- Tube Expansion and Tube welding machines

- Lathe Machines

- Radial Drilling Machines

- Heavy load EOT Cranes for material handling

- Spray Gun for painting and finishing

- Shot Blasting and Painting facilities

- CNC Drilling Machine

- Plate Shearing Machine

- Hydraulic press Machine

- Automatic Welding Machine

- Gas trains

- Electroslag strip cladding machine

- CNC Vertical Lathe Machine

- CNC Plasma Cutting Machine

- Column and boom automatic SAW and PAW

- Electro Polishing Machine

- High Tonnage rotators as well as positioners

We have manufactured and we have the capacity to handle and weld a diversity of materials like Carbon steel, Stainless steel, Duplex Steel, Titanium etc and can provide equipment lined with Rubber, FRP, PP, PVC, Glass Flake, Ceramic, PTFE,PVDF and various others .

We also have a Machine Manufacturing Capability of the following Metallurgy:-

- Carbon steel – All grades including NACE, HIC etc

- Stainless Steel – Austenitic , Ferritic , Duplex etc

- Clad Steel

- Non Ferrous – Copper , Nickle , Titanium , Brass , Hastelloy etc

- Other Materials – Lining – Rubber , FRP , PP , PVC , PTFE

Manufacturing Facility

02. Testing and Quality Control

Ketav Consultant is an ISO 9001-2008 Company.

With a full range of testing equipment and services available in-house and outsourced.

Testing and Quality assurance that we provide is as follows:-

- Hydraulic Medium Water Testing

- X – Ray

- Ultrasonic Test

- Paint Thickness Test

- Dye Penetrant Testing

- Tensile Testing

- Chemical Analysis

- Material Composition Test

Manufacturing Facility

03. Design & Engineering

At Ketav Consultant, we employ a Mechanical Design facilities with the latest software & qualified team of engineers. We have a variety of computerized manuals as well as thermal and mechanical design techniques to design tailored installations.

- Heat Exchange Institute Standards , ASME PTC 24, etc.

- Solid edge

- Auto CAD

- Unigraphics

- HTRI Xchanger

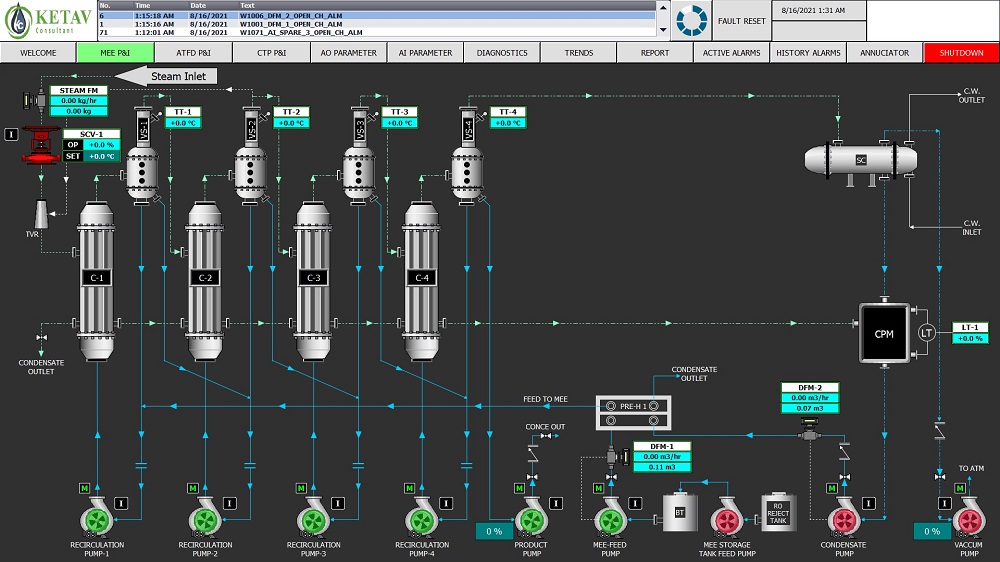

Pilot Trial Facility

We have an ultramodern Pilot Trial Facility to check feasibility and sustainability of offered solutions for water, waste-water and zero discharge which bring confidence to our esteemed clientele.

At Ketav Consultant Pilot Trial plant facility we have done more 3000 trials. This Ultra-modern and well equipped facility has helped us to install 500+ Projects in the last 15 years.

We at Ketav Consultant offers following trials:-

- Falling Film Evaporator Trial

- Forced Circulation Evaporator Trial

- Mechanical Vapour Recompression (MVR) Trial

- Zero Liquid Discharge System Trial

- Centrifuge Trial

- Agitated Thin Film Dryer (ATFD) Trial

- Salt Recovery Trial

- Solvent Recovery

Innovation and R&D Facility

We have our own R&D Team for inventing new technologies/ Ideas for Water, Waste-Water and Zero Discharge Solutions to establish “ZERO OPEX” theme.

Our R&D Team is continuously focusing on globally available technologies of water, waste-water and zero discharge solution to check feasibility which can be applied to our valued customers so that they could take advantage of technology advancement.

At Ketav Consultant, we have an ultra-modern lab facility to check water, waste-water and zero discharge solution effluent characteristic.

Having 35+ years of experience in evaporation process, we have started the following trials for evaporator process applications to reduce operating cost and thus reducing product manufacturing cost.

TO KNOW MORE ABOUT EVAPORATOR PROCESS APPLICATIONS PLEASE CONTACT US.

Meet Our Team

Ketav Team Comprises of :-

- 250+ experience employees who are catering various services in various divisions like process , proposal , sales and marketing , design and engineering , procurement , project , accounting and finance, HR and Admin , production , Research & Development and other services.

- Having 75+ engineers associated with us.

- Having 150+ employees serving Ketav Consultant from last 10 year.

- Having 75 + service engineers across the India to cater immediate support to our valued customer.

HR Policy

Our HR Policy:-

Creating a best working culture for professional excellence. this is result for a long term association between employee and employer.

Affirming our role as a company that supports communities and people without any difference and provide equal opportunity without any discrimination.

Developing and enhancing our employees’ professional skills by providing training and proficiency.

Health Safety and Environment(HSE) training on routine basis.