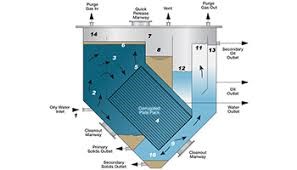

CPI (Corrugated plate interceptor) or TPI (Tilted Plate Interceptor)

CPI/TPI Separator is an unit operation for treatment of WTP/WWTP. CPI/TPI Or Corrugated / Tilted Plate Interceptor is a part of preliminary wastewater treatment for Oil Separation from effluent with moderate to high free floating Oil.

Process Description :-

The TPI consist of a number of inclined corrugated plates mounted parallel to each other usually at spacing of 2 cm. The raw water containing the oil and suspended solids passes between the plates from top. Laminar flow conditions are essential for the effective gravity separation of the water, the oil and suspended contaminants. In the course of passing from pack inlet to pack outlet, the oil floats upwards into the tops of the corrugations and rises up the incline of the plate to the surface of the system where it is removed by a skimmer. The sludge moves towards the bottom of the corrugations and slides down the incline of the plate spacing. From there the sludge is collected in a hopper to be discharged intermittently through a blow off valve. he equipment is designed to treat oil globule size of 50microns and above.

Target Impurities :-

- Free Oil & Grease, Floating Oil

Advantages :-

- Low Capital Cost

- Very Low Space

- Easy to cover for VOC and odor control.